产品描述:

上海工陶陶瓷有限公司(Gongtao)是中国最领先和先进的集设计、制造和营销的高科技陶瓷材料公司之一。品牌“上陶-SHANGTAO”成立超过20年。我们专注于氧化铝产品,氧化锆产品,氧化镁产品,有机硅氮化物产品和铝氮化物产品。我们已经开发出先进的技能和技术。我们的产品被广泛应用于电力,信息,电力,汽车和其他领域。

工业陶瓷:氧化铝陶瓷,氧化锆陶瓷,钛氧化物陶瓷,碳化硅陶瓷,氧化硅陶瓷,特种陶瓷,高频陶瓷,莫来石陶瓷,日用陶瓷,耐火陶瓷,电子陶瓷,纺织陶瓷,高纯度的氧化铝坩埚,电气陶瓷等

上海工陶陶瓷有限公司(Gongtao)严格遵守ISO9001质量管理体系。我们的产品广泛用于航空航天,矿山机械,电梯,电力,造纸,实验室,有色金属加工,电子加工,纺织机械等行业,SHANGTAO提供批发和零售,欢迎您的光临!

产品图片:

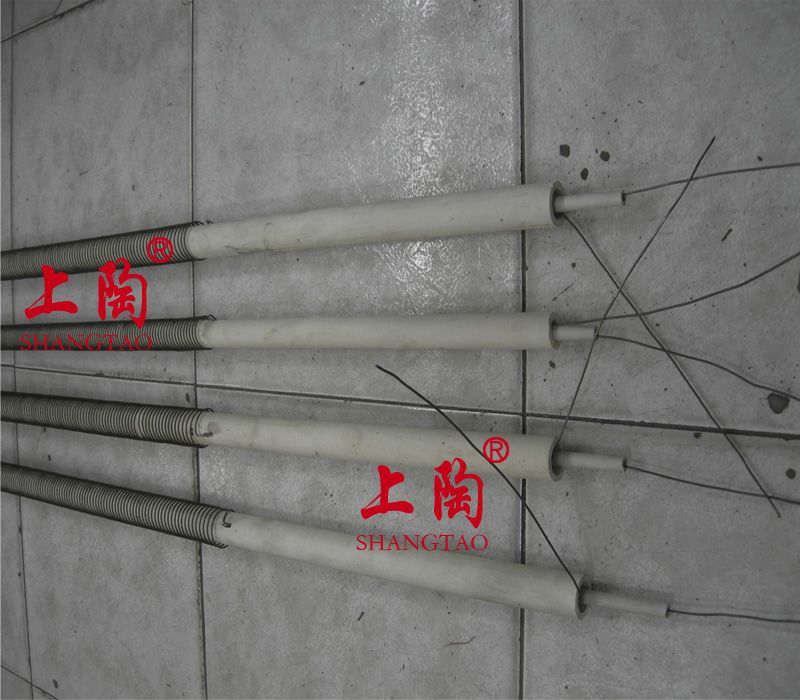

辐射管

产品简介

产品采用可控气氛的各种热处理炉中,为了避免燃料燃烧产物与工件的接触,或是为了避免炉气对电热元件的侵蚀,将燃料燃烧或电能转变的过程放在耐热钢管中进行,让热量通过管壁辐射给工件,这种装置称为辐射管。

电热辐射管是把电热元件封闭在保护套内,通电加热后,由套管间接地把热量辐射给炉衬和被加热工件。辐射管的加热适用于通保护气氛的和有腐蚀性气氛的炉子,如连续炉、滚筒炉、井式炉等等。

将电阻丝以轴向进行波折,即将单根电阻丝弯成U形,再互相串联或并联在一起的电热辐射管叫做波折式电阻丝辐射管。这种装配方式的辐射管,由于电阻丝的屏蔽作用降低,在管内较高的表面负荷下,也能确保长时间的使用寿命。

辐射管有下面几个优点:

(1)

可以保证炉内气氛的可控性

(2)

温度控制、安装和维修较方便,易于密封;

(3)

由于炉内无马弗罐,扩大了炉膛容积,提高了生产能力

(4)

加热能力强,效率高

(5)

节约了耐热钢材

辐射管

>>

产品使用材料

辐射管使用的电热合金材料应具有较高的电阻率,电热转化率高。由于辐射管放置在套管内,传热过程与一般敞露型电热元件不同,其热屏蔽大,升温过程中必须对元件温度进行控制,防止元件超温。辐射管封闭加热时,电热元件表面温度比炉膛温度高约

本公司生产的辐射管常使用Cr20Ni80(镍铬系)Cr

牌号 | Cr | Ni | AI | Mn | P | S | C | Fe |

Cr20Ni80 | 20-23 | 余量 | ≦0.5 | ≦0.6 | ≦0.02 | ≦0.02 | ≦0.08 | ≦1.0 |

Cr | 23-26 | ≦0.06 | 4-7 | ≦0.07 | ≦0.02 | ≦0.02 | ≦0.06 | 余量 |

Cr | 21-23 | ≦0.06 | 5-7 | ≦0.07 | ≦0.02 | ≦0.02 | ≦0.05 | 余量 |

Cr | 26-28 | ≦0.06 | 5-7 | ≦0.02 | ≦0.02 | ≦0.02 | ≦0.05 | 余量 |

Cr20Ni80使用在

Cr

辐射管

功率及表面负荷

表面负荷是指电热元件的单位表面积上所担负的电功率值。材料的表面使用负荷强度越高,材料的使用寿命越短,但材料的消耗量也越小。所以,要合理的选择元件的热负荷强度,使电热元件具有热效率高、寿命长、节省材料的综合效果。计算步骤如下:

(1)计算需要的基本数据

最高使用温度t(℃)

加热电功率P(W)

元件工作电压U(V)

发热区长度L(m)

(2)根据基本数据,结合电热元件的工作条件,确定使用的电热合金牌

(3)根据确定使用的电热合金牌照,参照已知数据,查附表得出电阻温度修正系数Ct。

(4)计算出材料总电阻=U2

Ct/P

(5)计算出每米材料电阻Rm=R/L,结合电热合金材料性质估算出材料直径D,再计算出电热元件总面积FO。

(6)由ω=P/FO得出材料的表面负荷ω,如果表面符合过大,则选择大的丝径。现国产辐射管因加热材料限制,表面符合应不超过2.0W/cm2,低温情况下可适当提高。

Introduction:

The

product is ued in controllable aural various heat

treatment furnace,to avoid

the contact of elding burning outcome or to avoid the

corrosion of furnace

gas to heating element.The process(the conversion of

elding burning or

electric

energy)

is put into refractory steel tube and let amount

of

heat radiate by wall of tube.This device is called as heater tube.

Electrothermal

heater

tube will close the heating element in the jacket,after electrify and

heat

up,the heat is indirectly radiated to furnace liner and workpiece to

be

heated by bushing.The heat up of heater tube is used in furnace with

going

protecting aural and corrodent aural,such as continuous furnace,roller

furnace,

pit furnace.

Twist

and

turn resistance wire in axial direction,that is,the single resistance

wire is

bended to U shape,then in series or parallel connection mutually.This

kind of

electrothermal heater tube is called bending resistance wire heater

tube.This

tube,because fall of screening of resistance wire,in intratubal

upper surface

load,can insure prolong life span.

The

advantages of tube:

1. The

controllability of aural inside furnace can be guaranteed.

2. The

control of temperature,assemble and maintainace are very convenient and can be

easy to

sealed.

3. The

cubage of hearth is enlarged and throughput is improved because of no muffle

pot

4. trong

heating ability and high efficiency

5. The

refractory steel material is save.

The

material of tube:

The

electrothermal alloy material that heating tube apply should be of

higher

resistance rate.The percent

conversion

of galvanothermy is high.Because the heating tube is put in the

bushing,the

process of heat transmission is different from that of open type

heating

element.Its heat shield is big.The temperature of element must be

controlled

at the course of temperature rise,to avoid temperature excursion

of

element.

When

the heater tube is closed and heated,the

surface temperature of

heating

element is higher roughly than temperature

of hearth by 100 C~150

C.So

temperature of furnace and atmosphere of temperature of furnace are

needed to

analysed.Choose correct heating material.

The

heater tube produced by gongtao company often

apply Cr20Ni80,Cr

Chemical

content of each material is as

below:

Item | Cr | Ni | AI | Mn | P | S | C | Fe |

Cr20Ni80 | 20-23 | margin | ≤0.5 | ≤0.6 | ≤0.02 | ≤0.02 | ≤0.08 | ≤1.0 |

Cr25A15 | 23-26 | ≤0.06 | 4-7 | ≤0.07 | ≤0.02 | ≤0.02 | ≤0.06 | margin |

Cr21A16Nb | 21-23 | ≤0.06 | 5-7 | ≤0.07 | ≤0.02 | ≤0.02 | ≤0.05 | margin |

Cr27A17Mo2 | 26-28 | ≤0.06 | 5-7 | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.05 | margin |

Cr20Ni80

is used between 500 C and 800

C,because of steady,single even solid

fusant

form,It

has good normal temperature and high temperature mechanics

property,even

electric physical property and good machining technics

property.Low use

temperature,long life,no easy damage ect are different from

Cr

electrothermal alloy

material.

Cr

800

C~1200C.The use temperature of these three material is hoisting in

turn.

Plasticity is low.High brittleness is the biggest shortcoming of Cr

when

use will make material precipitate

“CrFe”

type metal compound,which arose sharp fall of

alloy plasticity.

Severe embrittlement

phenomenon will appear.So Cr

alloy material

carry through formation,process and use,kept away from in this

temperature

range.

Power

and surface

load of heater tube

Surface

load,that is,the electric power value taking on on unit superficial

area of heating element.The higher surface use load

strength of material

is,the shorter life of material is,but the smaller the

wastage of material

is.So heating load strength of element should be chosen

reasonably,making the

heating element have general effect of high thermal

efficiency,long

life,material-save.Calculating step is as below:

1.Basic

data for calculation

The

highest use temperature t (C)

Heating

electric power P (W)

Working

voltage of element U (V)

Length

of heating zone L(m)

2.The

electrothermal alloy brand in use is

confirmed according to basic

data,combining with working condition of

heating

element.

3.Based

on the confirmed electrothermal alloy

brand in use,referring to known

data,check attached table and get coefficient

of correction Ct of resistance temperature.

4.Work

out total resistance of material=U2

Ct/P

5.Work

out resistance of per meter material

Rm=R/L,combine the property of

electrothermal alloy material and estimately

work out the diameter of

material D.Then work out total area FO of

heating

element.

6.The

surface load of material ω is gained by

ω=P/FO.If the load of surface is too

large,big diameter of wire should be

chosen.Currently because of limitation

of heating material, the surface load of

heater tube made in China should not

exceed 2.0W/cm2.It can be improved

properly in the condition of low

temperature.